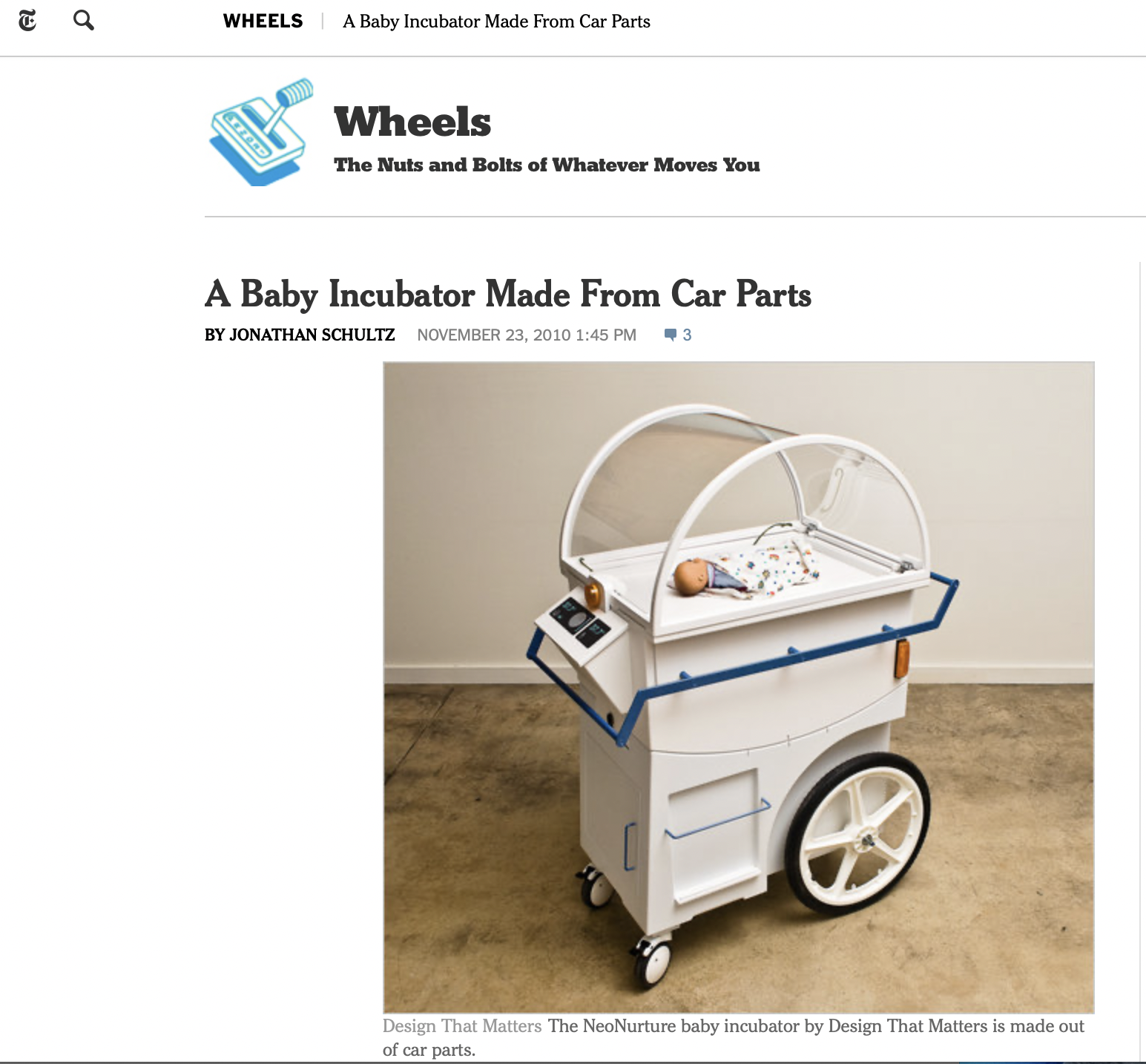

NeoNurture Car Parts Incubator

The goal of this project was to create a low-cost incubator and isolation unit for infant care in rural health clinics in developing countries using locally available parts and a familiar mechanical language.

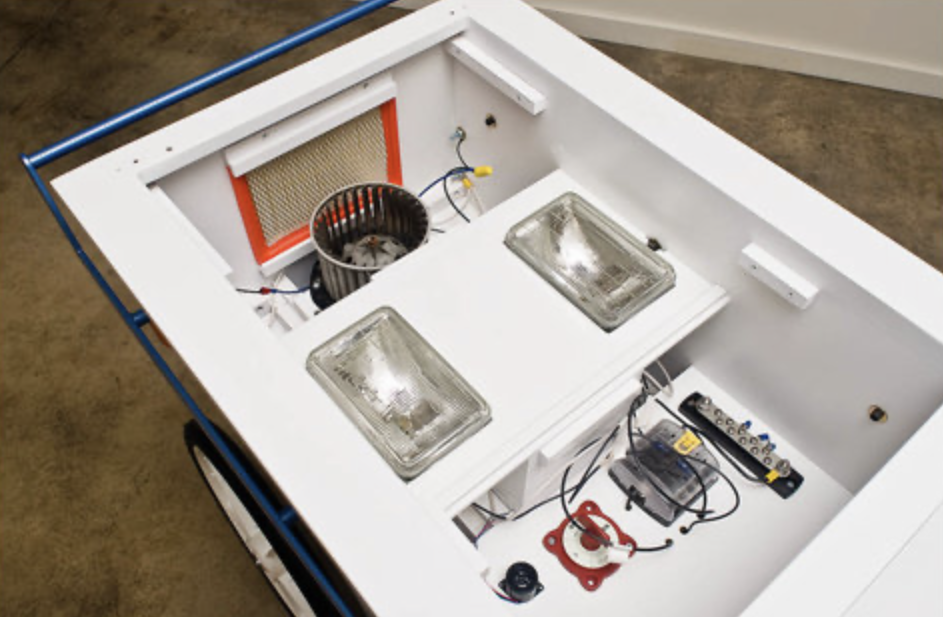

This baby incubator aimed to take advantage of an abundant local resource in developing countries: Toyota truck parts and the knowledge of auto technicians. Our goal was to leverage the existing supply chain of the auto industry and the technical understanding of local car mechanics. Among other components, this prototype used sealed-beam headlights as a heating element, a dashboard fan circulates convective heat, signal lights and a door chime serve as alarms, and a motorcycle battery and car cigarette lighter provide alternative energy sources.

After developing three prototypes of this incubator, it never went into mass production. However, breaking down a real Toyota truck and exploring how to build a functional incubator from the hundreds of parts from which it is constructed was more than a simple design exercise. It raised important questions that we, and others, continue to address in our work about testing products, collaboration, and how products are maintained, deconstructed and can exist responsibly in the world we live in? How will our products be used, what are the appropriate materials to build them with and how will they be maintained, deconstructed and exist responsibly in the world we live in?

NeoNurture car-parts incubator was exhibited at the Cooper-Hewitt museum’s National Design Triennial, Why Design Now? and kicked off Time magazine’s coverage of the 50 best inventions of 2010.

more projects